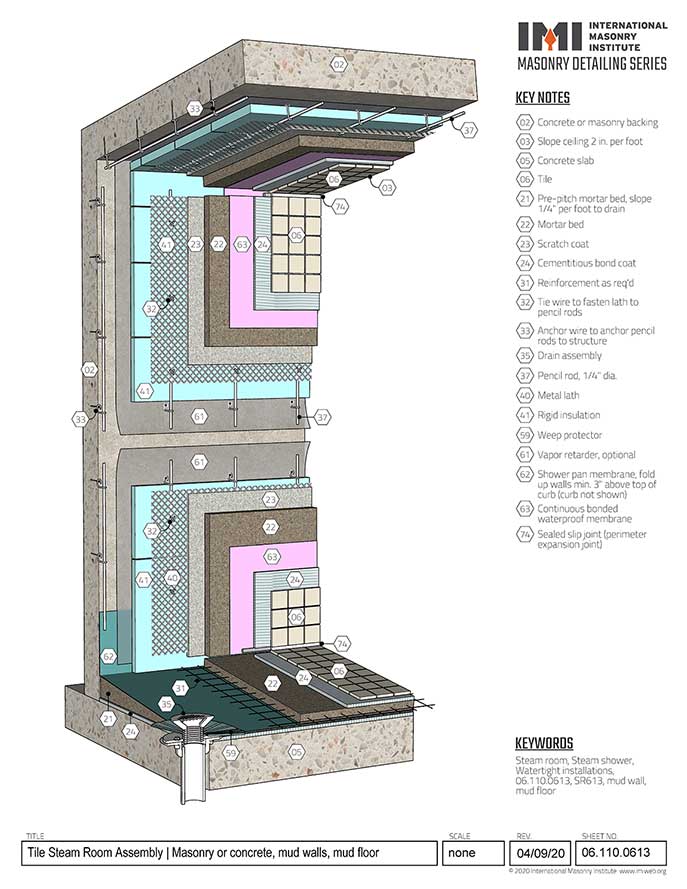

- Detail

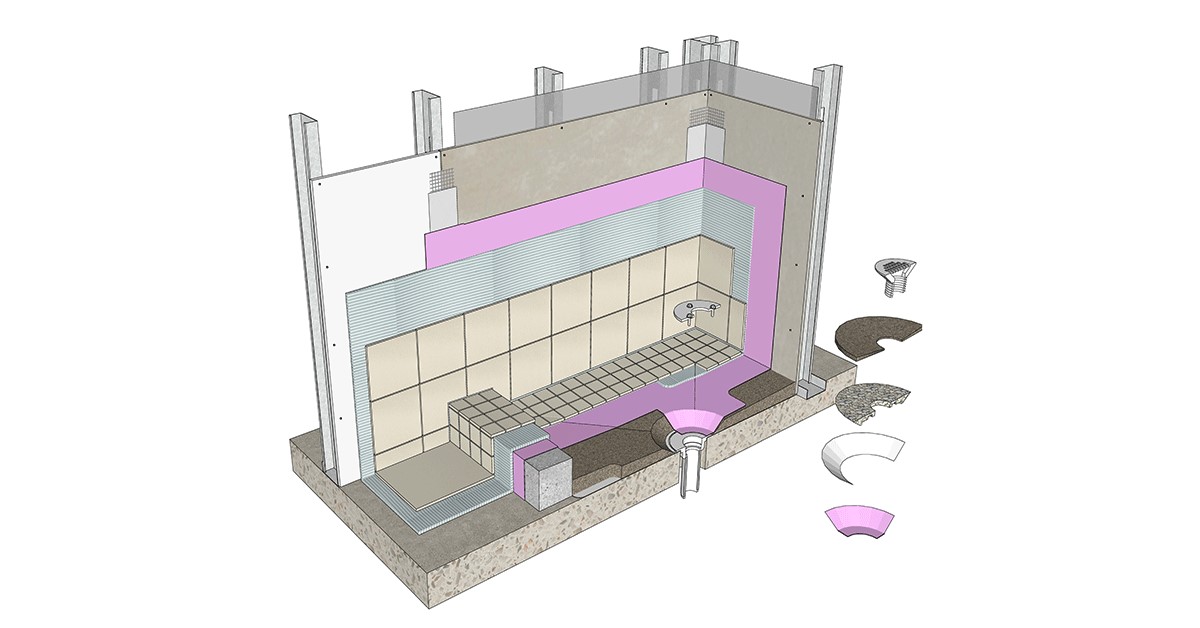

- 3D Model

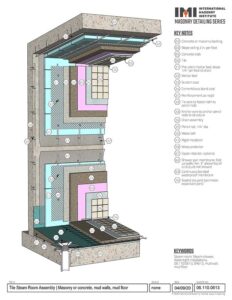

This detail, based on TCNA method SR613, illustrates a tiled steam shower or steam room assembly with masonry or concrete structure, mortar bed walls, and a mortar bed floor. The ceiling slopes 2″ per foot to prevent dripping of condensate. The bonded waterproof membrane must be continuous and must adequately limit vapor transmission. If bonded waterproof membrane has water vapor permeance greater than 0.5 perms and if steam shower is in continuous use, a secondary vapor retarder is required, which laps over the shower pan membrane. The mud walls and ceiling are keyed into a scratch coat with embedded lath and anchored to the structure with pencil rods and anchor wire. The floor comprises a pre-pitched mortar bed sloped 1/4″ per foot to drain, shower pan membrane tied into the two-stage drain assembly, and a reinforced mortar bed. The tile is adhered with a bond coat of modified thinset mortar.