Material Selection

Types of Tile

While there’s a tile for every job, not every tile is appropriate for every application. ANSI A137.1 American National Standard specifications for Ceramic Tile categorizes tile into 5 types:

- Mosaic tile

- Quarry tile

- Glazed wall tile

- Pressed floor tile

- Porcelain tile

The tile trade also encompasses:

Tile and the craft of tile setting aren’t limited to the types of tiles listed above. Manufacturing technology is constantly evolving, and as new materials come to market, BAC contractors and craftworkers are on the leading edge of training and installation for all tile types.

Materiality of Tile

ANSI and ASTM standards establish the visual, physical, and environmental performance of tile and tile assemblies in the context of design.

The visual attributes of tile include its uniformity of color, shade, and texture, as well as dimensional stability. The physical attributes of tile define how it behaves physically, including its water absorption, durability, and bond strength.

The visual and physical attributes of the material, which are tested and measured to U.S. standards, work in concert to achieve assembly-wide qualities, including health benefits, ease of maintenance, fire and smoke resistance, watertightness, and design versatility. The environmental variables may greatly impact the design of the assembly. When considered together, the visual, physical, and environmental attributes of tile inform the materiality of tile as a finish assembly. This materiality should inform the design professional, specifier, owner, and end users as they make their material selections.

Layout and Lighting

Layout

Laying out a tile wall or floor can be one of the most complex and important activities preceding the installation, and one that impacts the design in a profound way. Layout is often so critical to the design that the architect or designer will show it in the drawings and expect the layout to appear exactly as shown. Unfortunately, certain conditions may interfere with the ideal layout shown on the design drawings. Variations in as-built room dimensions, slight changes to the size of the tile used and/or the grout joint width can impact the tile layout, causing the installers to make important decisions in the field.

Qualified tile installers are accustomed to installing material in accordance with the layout guidelines described in ANSI A108.02 American National Standard Specifications for the Installation of Ceramic Tile, General Requirements: Materials, Environmental, and Workmanship. You can expect a qualified installer to:

- Center and balance areas of tile when possible, usually with no cuts smaller than half size, placing cut tiles on the outer edges of the field.

- Understand the hierarchy of maintaining alignment of grout joints relative to the uniformity of grout joint width, which can be a challenge, especially when the dimensional variation of the tile is at the higher end of allowable ranges.

- Understand the ANSI requirements for minimum grout joint width in terms of relationship to the dimensional variation of the tile supplied. Help manage expectations of grout joint width, uniformity, and alignment by interpreting ANSI for the owner or design professional.

- Understand which bonding patterns are recommended for large format tile and which are not, due to the potential for excessive lippage resulting from offset bonding. Qualified installers lay out and install large format tile in a way to minimize the perception of lippage.

Lighting

Just as important as a room’s tile layout is the architectural lighting under which the tile installation will be viewed. Smart design professionals understand the risks of wall wash lighting and its potential to highlight even small amounts of lippage in a tile installation. It’s best to place ceiling lights a safe distance away from wall tile to present the tile under optimum conditions.

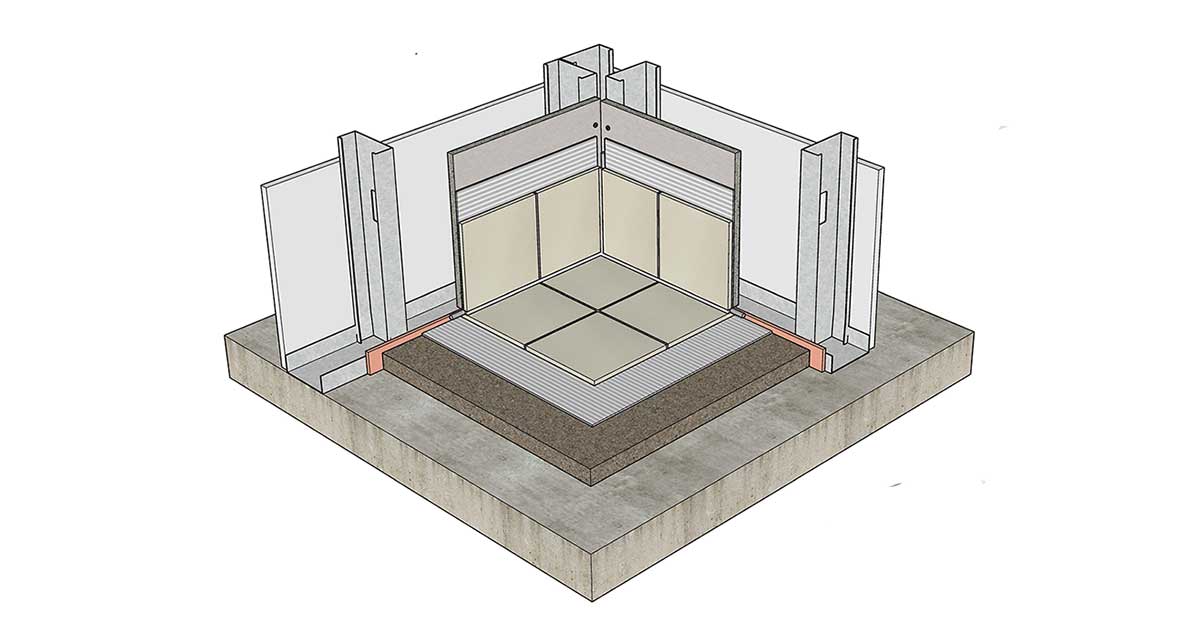

Movement Control

Guidance for Accommodating Movement

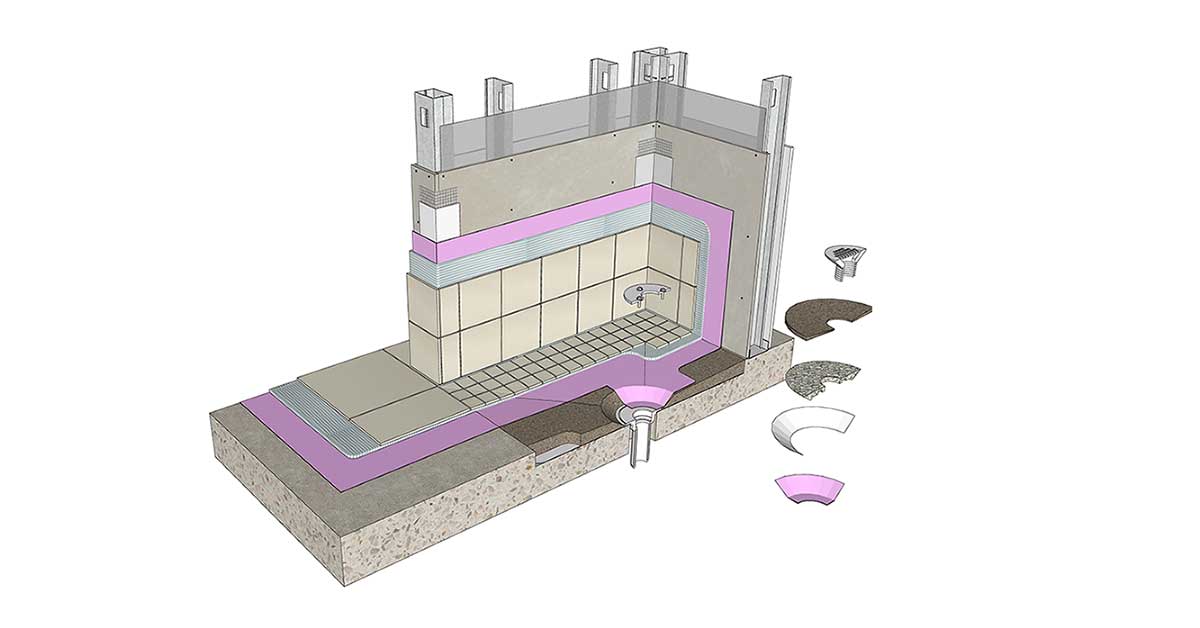

As with all building material, tile assemblies should be designed to accommodate movement in order to avoid cracking. According to ANSI A108, movement joints are required for tile work in vertical and on horizontal surfaces, both interior and exterior. Since the primary movement of ceramic tile is expansion, it’s correct to refer to these movement joints as “expansion joints” (not “control joints”) in the context of the tile assembly. The general term “movement joint” may also be used.

The tile assembly should be installed with expansion joints directly over all construction, cold, contraction, control, expansion, saw-cut, seismic, and isolation joints in the substrate. Expansion joints should also be included where substrate materials change or change plane, including terminations of tile that abut restraining or dissimilar surfaces. Expansion joints should extend all the way through the tile assembly to the substrate.

It’s the design professional’s responsibility to locate and detail expansion joints in the tile assembly. For rule-of-thumb suggestions on expansion joint location and frequency, refer to the EJ171 section of the TCNA Handbook. If a detailed analysis is desired, EJ171 offers formulas for calculating movement based on the tile’s coefficient of linear thermal expansion. Design professionals can also refer to ASTM C1472 Standard Guide for Calculating Movement and Other Effects when Establishing Sealant Joint Width.

Substrate Preparation and Requirements

Preparation By Other Trades

Preparation by other trades is an important topic to grasp in any project, especially since work assignments to specific trades vary by project and by GC or CM. The construction contract should clearly define where the work of other trades stops and the work of the tile contractor starts.

Generally, the tile contractor installs the tile work, but depending on the project, there are many additional work activities that may fall within the tile contractor’s responsibility. This includes, but isn’t limited to, installing backer board, remediating wall and floor substrates that don’t meet flatness requirements, installing accessories like flashings, membranes, and copings, installing bathroom fixtures and accessories like grab bars or towel rods, and repairing penetrations through the tile assembly made by others. Tile contractors are also qualified to perform related activities like protecting newly-installed tile work and water testing tile assemblies if included in the contract.

All work done prior to the tile work by trades other than the tile contractor that interface with the tile assembly must meet the requirements for deflection, moisture content, surface profile, flatness, and other criteria required for a tile finish as stated in the TCNA Handbook and ANSI standards.

Each of the tile installation methods appearing in the TCNA Handbook has a section on Preparation by Other Trades indicating the materials and/or preparation work required of other trades preceding the work of the tile contractor. ANSI A108.01 and A108.02 provide detailed information for related trades regarding preparation for tile work.

Substrate Preparation

The job of a tile setter begins long before the first tile is laid. The ability to assess existing conditions and to remediate where necessary (assuming substrate remediation is in their contract) is one of many critical skills the trade requires. Union tile installers are trained to know substrate flatness requirements, how to assess existing conditions, and the protocols for reporting substrates that are potentially unsuitable to receive tile. Any finished tile installation will only look as good, and perform as well, as the substrate behind it.

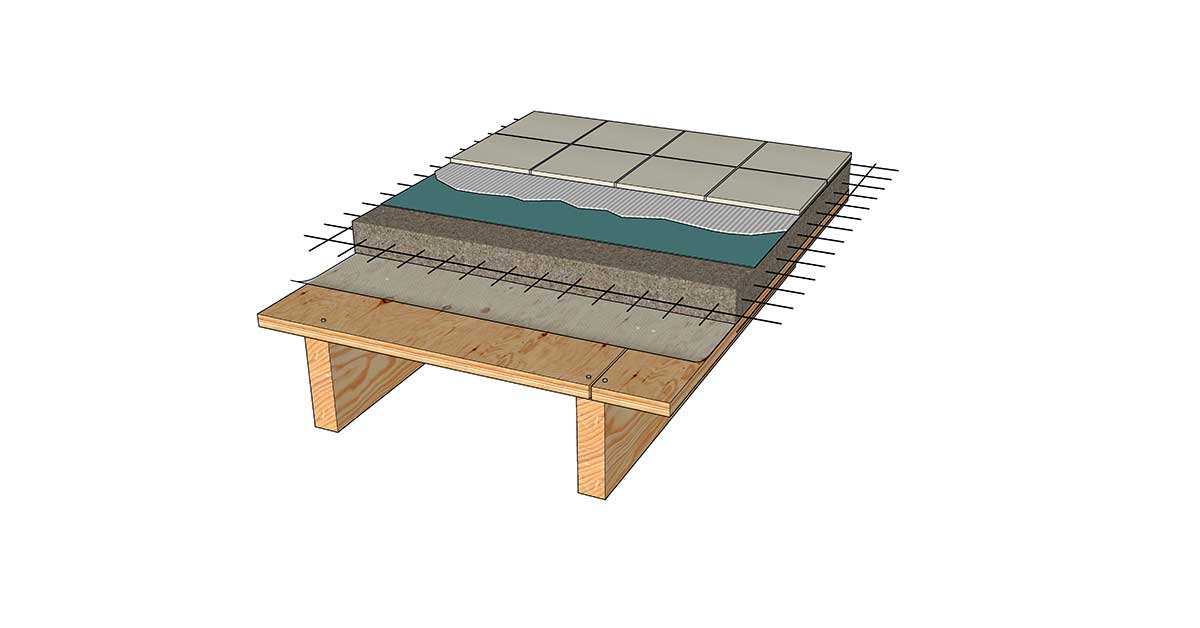

According to ANSI A108.01, “Ceramic tile can be installed over horizontal and vertical building surfaces by one or more methods described in these documents. Tile can be installed directly over sound, clean, and dimensionally stable surfaces with one of the thin-set methods or with a mortar bed method.” The standard goes on to describe the requirements for wall backing systems of concrete, masonry, backer boards, gypsum plaster, and wood. The standard also discusses floor backing systems of concrete slabs-on-grade, elevated concrete slabs, terrazzo, existing tile, steel plate, and wood.

Each of these floor and wall substrates presents a unique set of requirements with respect to deflection, moisture content, surface profile, and their ability to bond with the tile assembly. Certain setting methods are acceptable for some substrates, but not others. All substrates must meet flatness requirements.

Refer to ANSI A108.01 General Requirements: Subsurfaces and Preparation by Other Trades for a detailed discussion of substrate requirements.

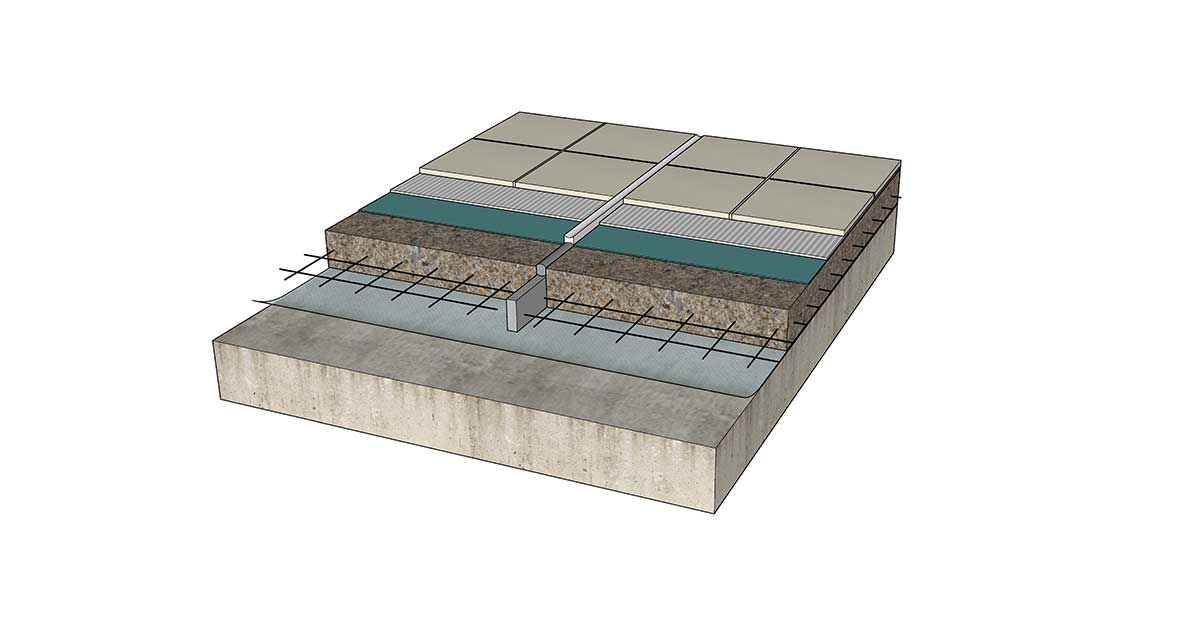

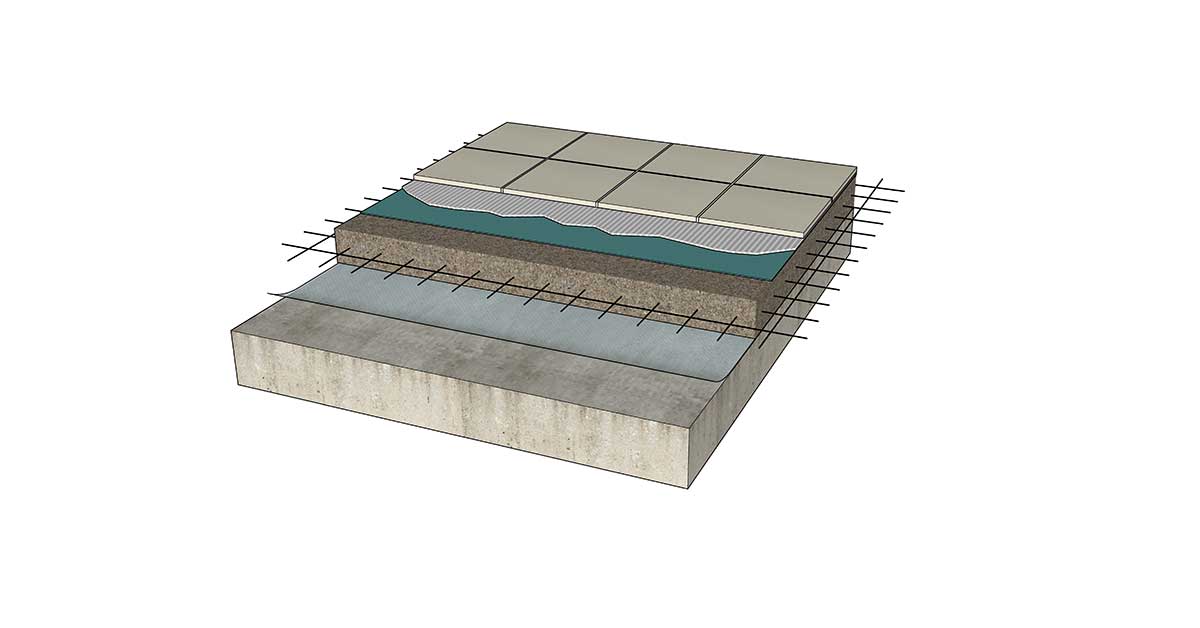

Installation Methods

According to ANSI A108.01, “Ceramic tile can be installed over horizontal and vertical building surfaces by one or more methods described in these documents. Tile can be installed directly over sound, clean, and dimensionally stable surfaces with one of the thin-set methods or with a mortar bed method.”

The methods for installing tile are outlined in detail in the installation standards contained in ANSI A108, and are summarized here:

- A108.1A: Installation of Ceramic Tile in the Wet-Set Method, with Portland Cement Mortar

- A108.1B: Installation of Ceramic Tile on a Cured Portland Cement Mortar Setting Bed with Dry-Set or Latex-Portland Cement Mortar

- A108.1C: Contractor’s Option: Installation of Ceramic Tile in the Wet-Set Method with Portland Cement Mortar or Installation of Ceramic Tile on a cured Portland Cement Mortar Setting Bed with Dry-Set or Latex-Portland Cement Mortar

- A108.4: Installation of Ceramic Tile with Organic Adhesives or Water Cleanable Tile-Setting Epoxy Adhesive

- A108.5: Installation of Ceramic Tile with Dry-Set Portland Cement Mortar or Latex-Portland Cement Mortar

- A108.6: Installation of Ceramic Tile with Chemical Resistant, Water Cleanable Tile-Setting and -Grouting Epoxy

- A108.8: Installation of Ceramic Tile with Chemical Resistant Furan Resin Mortar and Grout

- A108.9: Installation of Ceramic Tile with Modified Epoxy Emulsion Mortar/Grout

- A108.12: Installation of Ceramic Tile with EGP (Exterior Glue Plywood) Latex-Portland Cement Mortar

- A108.14: Installation of Paper-Faced Glass Mosaic Tile

- A108.15: Alternate Method: Installation of Paper-Faced Glass Mosaic Tile

- A108.16: Installation of Paper-Faced, Back-Mounted, Edge-Mounted, or Clear Film Face-Mounted Glass Mosaic Tile

The first 3 methods listed, A108.1A, A108.1B, and A108.1C describe mortar bed (a.k.a. mud) methods, and the others describe thin-set methods.

The TCNA Handbook illustrates many examples of different installation methods, both mud set and thin set.

The setting materials and other components within each of the installation methods behave uniquely in the assembly, making it imperative to have skilled tile installers who understand the intricacies of working with the method specified.

Grouting and Finishing

Grouting, Cleaning, and Protecting Your Tile Assembly

The protection of finished tile work, final grouting, cleaning, and sometimes sealing of the finished tile assembly is the final stage of installation. These are important components of a successful and long-lasting tile assembly. BAC signatory contractors employ trained tile finishers to perform these critical tasks.

When it comes to grouting and cleaning, there are many different types of tiles and grouts that require different application and cleaning procedures. The tile contractor should follow the product manufacturers’ instructions and recommendations. ANSI A108.02 contains useful general information on cleaning tile.