- Detail

- 3D Model

Double click to activate the 3d render.

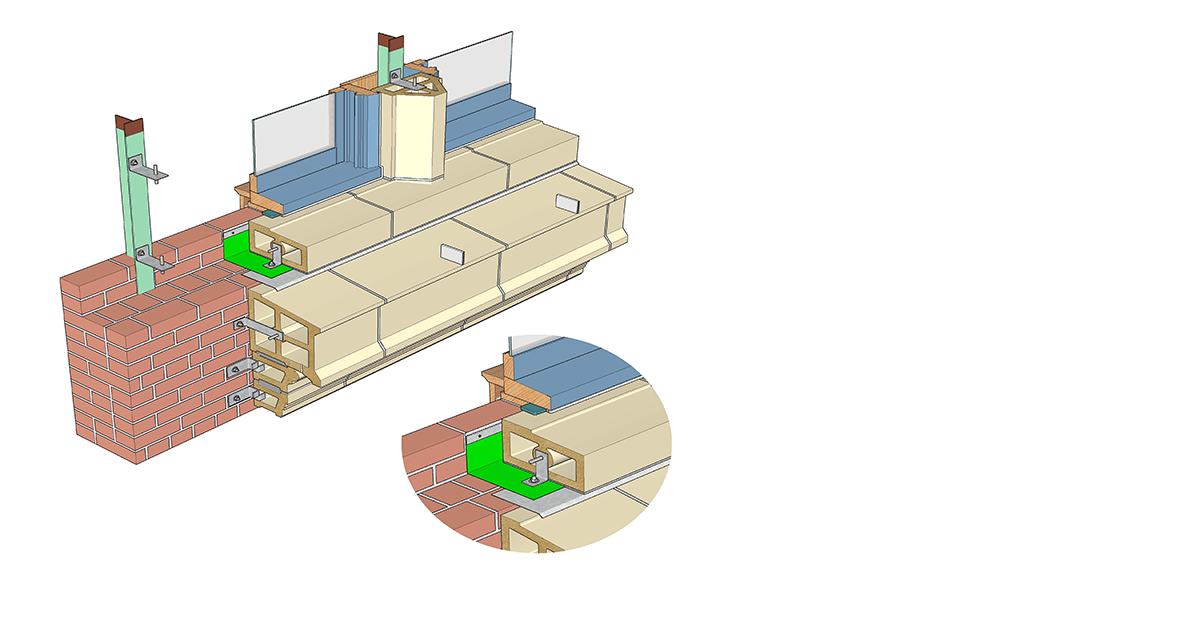

This detail illustrates a modern rebuild strategy for replacing existing architectural terra cotta (TC) cornice, balustrade parapet, and accessory units. The existing TC is replaced with new extruded TC units, installed not filled, with weep holes at the underside of each overhanging unit; each secured with new stainless-steel anchorage. In restoring and rebuilding these types of historic wall systems, moisture mitigation is critical to their long-term preservation and performance. Moisture management measures in this detail include horizontal skyward-facing joint treatment of sealant or lead T-caps, an integrated flashing system installed in the cornice, and stainless-steel through-wall flashing under the coping. The flashing system in the cornice includes a self-adhering flashing secured by a termination bar with continuous sealant, a stainless-steel drip edge, and weeps in the vertical joints. Accessible existing structural steel is also protected by cleaning and coating. These TC rebuild details illustrate general best practices. Specific inhibiting coating project conditions, configuration, and details will vary and shall be determined by the design professional.

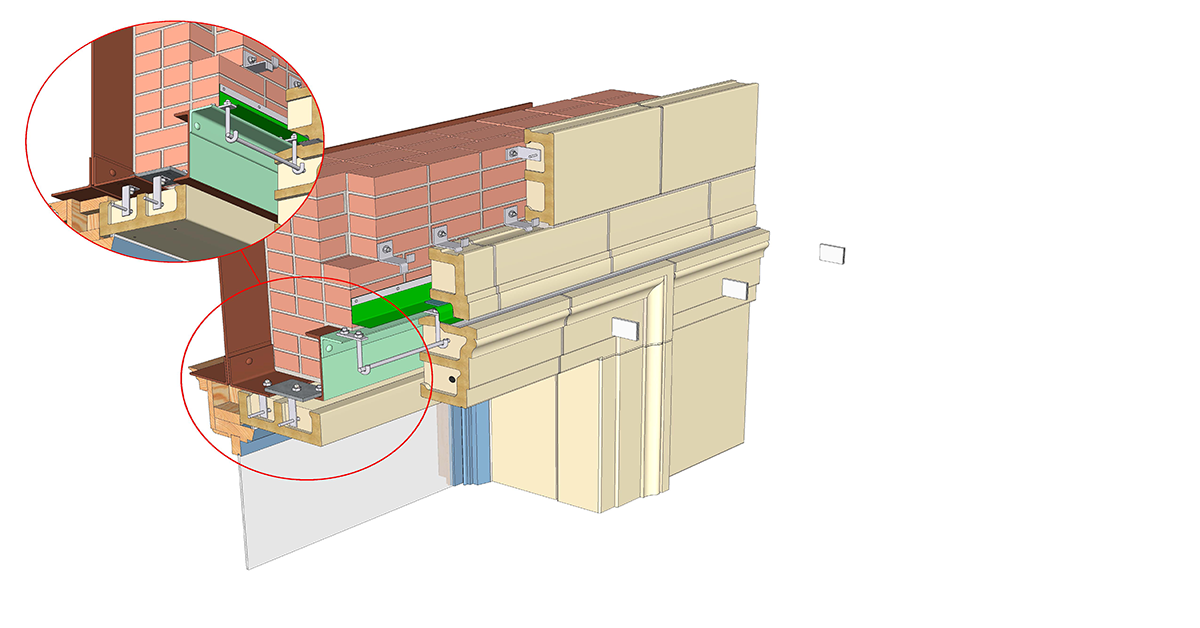

We’ve also included a modern rendering of an original detail in Plate 25 of Terra Cotta Standard Construction, published by the National Terra Cotta Society, in 1914. This detail is a general example of appropriate architectural terra cotta design and detailing at the time of publication. Specifically, it illustrates an example of an architectural terra cotta cornice, balustrade parapet, and accessory units. The units are anchored to a transitional wall system, consisting of a multi-wythe masonry backup wall with structural steel support. The architectural terra cotta is hand-pressed and attached with steel anchorage. Though the details in Terra Cotta Standard Construction were intended to illustrate general best practices of terra cotta construction, specific project construction and conditions vary.