- Detail

- 3D Model

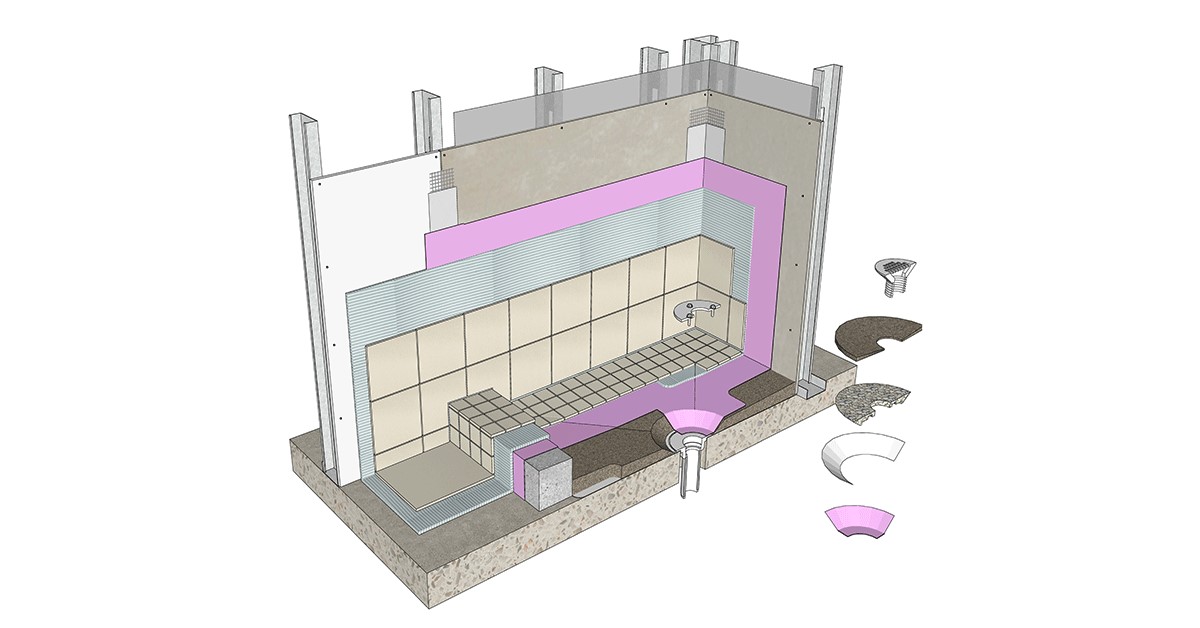

This detail, based on TCNA method SR614, illustrates a tiled steam shower or steam room assembly with wood or metal stud framing, cement board walls and ceiling, and a mortar bed floor. The ceiling slopes 2″ per foot to prevent dripping of condensate. The bonded waterproof membrane must be continuous and must adequately limit vapor transmission. If the waterproof membrane has water vapor permeance greater than 0.5 perms and if the steam shower is in continuous use, a secondary vapor retarder is required, which laps over the shower pan membrane. If steel studs are used, they must be 20 gauge or heavier and spaced 16″ o.c. maximum to limit deflection. Shims may be required behind the backer board to account for the thickness of the shower pan membrane, the thickness of supports for grab bars and other accessories affixed to the studs, and to ensure the walls are flat. The floor comprises a pre-pitched mortar bed sloped 1/4″ per foot to drain, a shower pan membrane returned behind the backer board and tied into the two-stage drain assembly, and a reinforced mortar bed. The tile adheres with a bond coat of modified thin-set mortar.