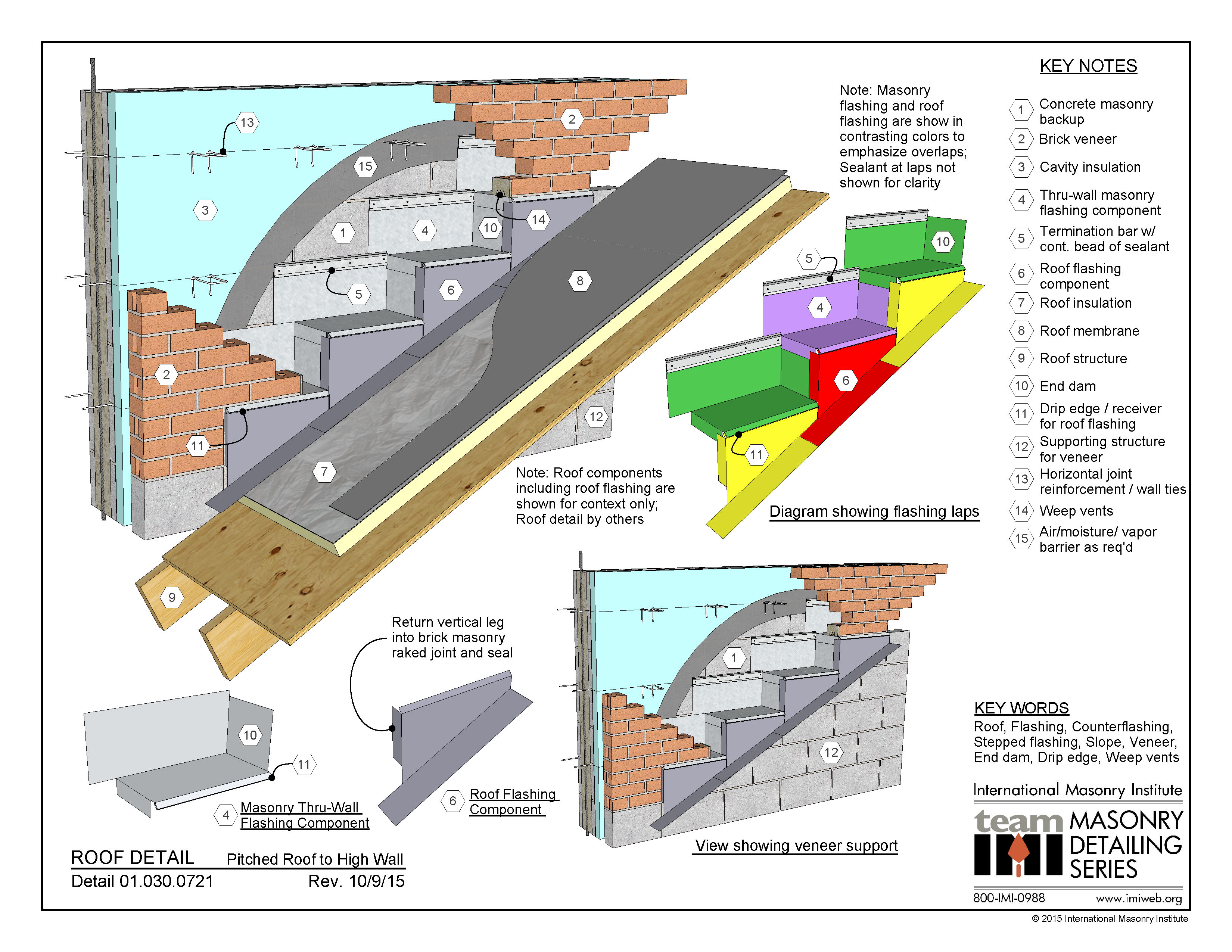

This detail illustrates a sloped roof terminating into a higher masonry veneer wall. The veneer is supported below the roof by CMU or other supporting structure. Above the roof, a series of short masonry flashing components4 are mechanically fastened to the backup wall using a termination bar with continuous sealant5 along the top; these short pieces of masonry flashings terminate outside the face of the masonry with a drip edge that also functions as a receiver for the roof flashings.11 The masonry flashings terminate in the wall on the high end with a vertical end dam,10 and on the low end with a downturn which laps vertically over the adjacent lower masonry flashing. This series of masonry flashings, sometimes called “baby tins” serves to collect water which enters the wall behind the veneer, and to divert that water back out of the wall through the weep vents14 and onto the roof for proper drainage. A series of short roof flashing components6 tie into the receiver ends of the masonry flashings. The bricklayers are responsible for the masonry wall including the masonry flashing, and the roofers are responsible for installation of the roof flashing and the roof assembly. Tying the two systems together properly is critical for a watertight wall/roof interface.

3D Detail

Explore this 3D detail and download the Sketchup model in the 3D Warehouse.